Services

CSI is a full-service cable assembly manufacturing company. We have a complete line of wire processing machines and testing equipment, please feel free to explore all of our special services, you will find that CSI has the capabilities to handle all you wire assembly needs.

Cirrus Signature 2000 Testing Equipment

Three Stage Coax Stripping Machine

Molex TM-42 Crimping Press

Molex 301 ATP Terminal Crimping Press

Schleuniger CS9050 Cut and Strip Machine

Schleuniger US 2015 Tubing and Ribbon Cable Cutting

Sumimark Tubing Marking System

Schleuniger 2015 Wire Stripping Machine AMP G Press

Artos CS-26A High Speed Wire and Cable Cutting Machine

Assembly & Harnesses

CSI builds many type of cable assemblies and wire harnesses to any customer specification. Our vast inventory of wire, cable and tubing coupled with our state-of-the-art wire production equipment allows us to produce many requirements right from our own inventory, providing you with the competitive edge you need.

Heat Shrink Labels

The Sumimark Marking System

Our Sumimark System Can Create Permanent

Heat Shrink Markers on the Following

Tubing Manufactured by Sumitomo

- SUMIMARK SM12 - FLEXIBLE POLYOLEFIN - 2 to 1 SHRINK - MIL-I-23053/5 CLASS 1&3

- SUMIMARK SM23 - OVEREXPANDED FLEXIBLE POLYOLEFIN - 3 to 1 SHRINK - UL RECOGNIZED

- SUMIMARK SM25 - DUAL WALL FLEXIBLE POLYOLEFIN THICK WALL ADHESIVE M23053/4 CL3

The high-resolution printing yields clear text and crisp bar codes. Logos can be scanned and printed with exceptional quality. Our menu-driven software provides a variety of text sizes, multi-line printing capabilities and variable cut lengths for a large range of tubing sizes with uncommon versatility. Our SUMIMARK Marking System can meet your heat shrink marker needs, with MIL-M-81531 Performance.

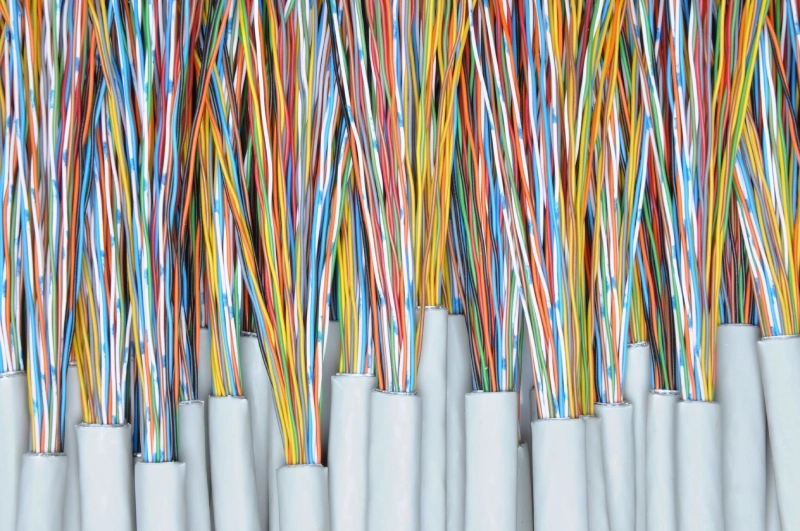

Custom Composite Cables

Custom composite cables are what we specialize in. It's the best way to integrate all of your wiring needs for different applications based in common locations.

Combining different types of wire and cable under an expected jacket speed up installations eliminates the guesswork in installation estimates, reduces pulling stress on the wire, and cuts down on costly installation errors. Our advanced coloring, striping, and printing capabilities allow us to mark wires virtually any way that could be specified, making installation a breeze. Custom cables save on total project costs through the quicker, easier installation of one cost-efficient cable.

This custom composite cable features 15 conductors of 24 gauge overall shielded and jacketed, six shielded pairs of 24 gauge with an overall jacket, four conductors of 18 gauge shielded and jacketed, four individually jacketed twisted pairs of 18 gauge, six single conductors of 24 gauge, 4 RG 58A/U coaxial cables and two vent tubes all under an overall red polyurethane jacket.

This composite cable consists of an inner core of 8 striped coaxial cables and an outer core of 15 pairs of PTFE-insulated 26-gauge silver-platted copper. It has an 85% tinned copper braid and an overall black PVC jacket.

This custom cable features an inner core of 4 shielded pairs of 18 gauge. The next pass consists of 10 shielded pairs of 16 gauge, and the outer pass consists of 16 shielded pairs of 16 gauge. There is an overall foil shield, all under a black PVC jacket.

View our custom composite cable case studies for more examples of cables designed and manufactured for the precise needs of our customers.

Contact Colucci Sales, Inc. today for information on how we can help with your composite cable needs.